Pushing boundaries in thermal shift assays towards 1536 wells

Challenges of Drug Discovery - High attrition rates and costs risk

Today, the vast majority of drug candidates—90%—fail during clinical trials, leading to significant financial burdens for the pharmaceutical industry. To alleviate these costs, it's crucial to make informed strategic decisions early in the drug development process, ensuring precise selection of candidates for clinical progression. Embracing cutting-edge, efficient, and scalable technologies in High Throughput Screening (HTS) is essential for enhancing success rates and managing economic challenges more effectively.

Different phases of the drug discovery process

Thermal shift assays (TSA) - An efficient method for screening large compound libraries

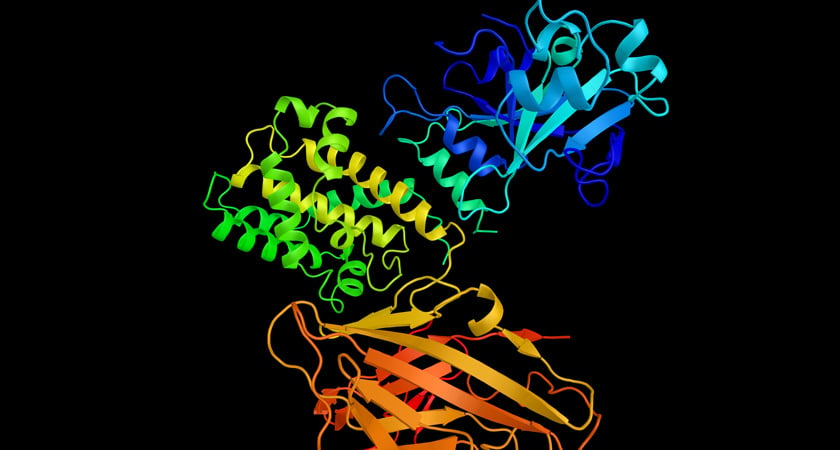

Thermal shift assays (TSA) are a vital technique in drug discovery, used to assess the stability of proteins in the presence of potential drug compounds. By measuring changes in the melting temperature of a protein upon binding with a ligand, researchers can identify promising candidates that stabilize or destabilize the protein. TSAs are highly advantageous in drug discovery because of their high-throughput capability, cost-effectiveness and simplicity. They require minimal sample amounts and deliver rapid results. As a label-free technology, the experimental setup is streamlined and applicable to a wide variety of proteins. This efficiency empowers early-stage screening of potential drug candidates, positioning TSAs as an ideal choice for primary screenings.

Principle of the thermal shift assay

TSAs excel at rapidly screening vast compound libraries in minimal time. Yet, to fully harness their capabilities, transitioning to screening in a 1536 well format should be the ultimate objective. This shift optimizes efficiency, allowing for comprehensive exploration and enhanced throughput in drug discovery endeavors.

Take the next step in ultra-high throughput TSAs

Introducing Greiner Bio-One's 1536 well thermal plate for faster, more efficient screenings. With its low-volume plate design, the plate facilitates miniaturized and cost-effective ultra-high throughput TSAs. Reduce your cost per data point compared to traditional 384 well solutions and increase your throughput fourfold.

The new 1536 well thermal plate from Greiner Bio-One

The automation-friendly plate exhibits exceptional thermal stability and conductivity. This is achieved by merging a rigid ANSI-compliant polycarbonate frame with a polypropylene plate meticulously designed for highly sensitive thermal applications. Thanks to its ultra-thin 300 µm flat bottom design highly uniform heat transfer is ensured leading to consistent and precise results for all wells. Furthermore, the white pigmentation secures an optimal signal-to-noise ratio, enabling precise optical readouts.

Co-innovation in a strong partnership

As innovation doesn't happen in a vacuum, this development stands in the tradition of our collaborative projects with the Bayer AG, which, back in 1997, already led to the groundbreaking introduction of the 1536 well format. In this spirit, a dedicated team of scientists and engineers from Bayer and Greiner Bio-One have embraced this new challenge - with success!

Are you ready to take the next step, too?

Contact our expert