A smarter plate design for HTS transwell migration assays

From cancer to cardiovascular disease, researchers are increasingly focusing on mechanisms of cell migration and invasion as a rich seam for drug discovery. With their versatility, ability to mimic physiological conditions, and suitability for high-throughput, transwell assays are an excellent choice for quantifying cell migration and invasion in drug discovery. While there are many parameters to consider when scaling up and optimizing these assays for high-throughput, one of the most crucial success factors is often overlooked—the plate design. In this article we take a look at three of the most common challenges encountered with 96-well devices for transwell migration assays, and what features to look for in an HTS plate to maximize your chances of success.

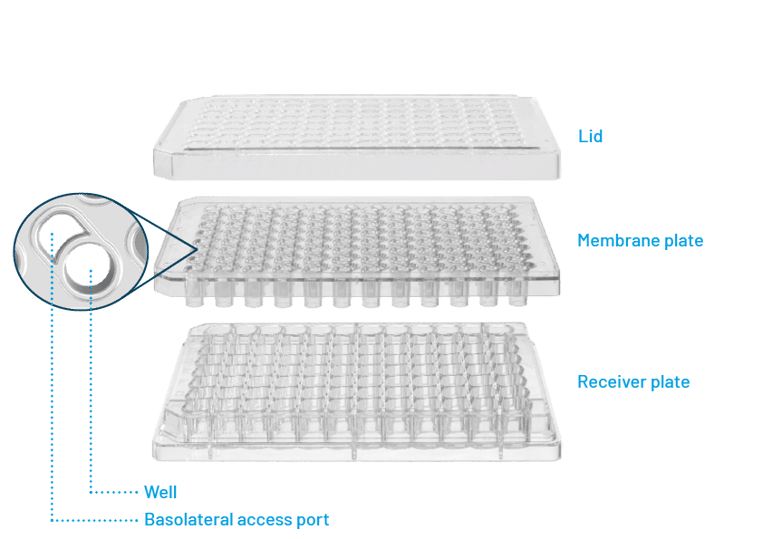

Anatomy of a 96 well transwell assay device

The transwell migration assay chamber is a 2-compartment system. For high-throughput applications, the assay device typically comprises a 96-well porous membrane insert (or set of inserts), and a corresponding receiver plate. When assembled, these components must fit together precisely to form the upper and lower compartments of the assay chamber.

Figure 1: Design of membrane insert plate system.

Sounds simple – what can go wrong?

With such a straightforward system, the possibility for problems with the assay plate is often overlooked. However, there are a number of pitfalls that can arise from a non-optimal plate design. Three of the most common are:

1. Basolateral dispense/aspiration mishaps

Basolateral access ports are a key feature in transwell assay plate design. They enable aspiration and addition of reagents to the lower compartment without the need to disassemble the system. If the ports are too small, pipette tips can get stuck in them, sometimes disrupting automated runs and potentially pulling the insert away from the receiver plate. This compromises the integrity of the chamber contents, potentially leading to liquid spillover and incorrect volumes.

2. Wicking effects

Accurate positioning of the insert relative to the walls of the receiver plate is crucial. If the insert is too close to the wall, capillary forces wick media up the wall, creating severe volume problems.

3. Poor reproducibility

Membrane flatness is particularly important for establishing optimal and reproducible cell culture conditions. If not carefully quality-controlled this can be an insidious source of assay variability and poor reproducibility.

ThinCert® HTS inserts for high-throughput assays – success by design

The new 96 well HTS insert from Greiner Bio-One is the latest addition to the ThinCert® family. As well as extending the range of pore sizes for compatibility with a wide range of migratory cell types, every aspect of the insert has been carefully considered and optimized to minimize common problems with transwell migration-invasion assays.

- Self-centred design: Precise centering and optimized fit of the membrane plate prevents media wicking and provides optimal conditions for cell culture

- Pore sizes suitable for a wide range of migratory cell types: Choice of 3 µm or 8 µm suitable for evaluating a wide range of migratory and invasive cell types, including cells with small nuclei such as lymphocytes, and most epithelial and fibroblast cell type

- Excellent membrane flatness: design and quality control measures ensure membrane flatness for optimal culture conditions in every well and every experiment

- High permeability and transparency: for optimal diffusion rates and optical features.

To learn more about the new ThinCert® 96 well HTS inserts and how they can accelerate your high-throughput chemotaxis, migration and invasion assays, talk to one of our experts.