Choosing the Optimal Microtiter Plate for Best Results

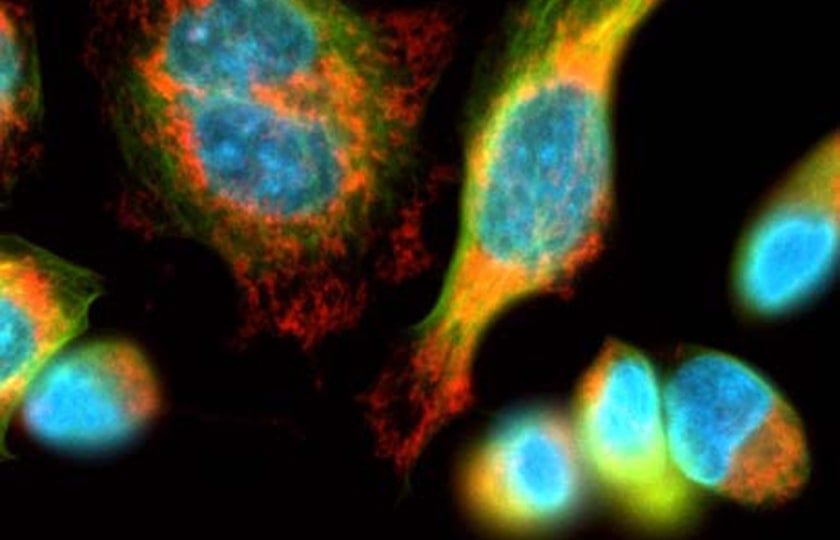

The gold standard in high-throughput microscopy is still glass microtiter plates (e.g., Greiner Bio-One CELLview plates). However, cyclic olefin materials have similar optical properties and offer further advantages such as lower cost and a wide range of surfaces for tissue culture and other applications. Inter- and intra-well flatness, and transmission of low UV wavelengths are critical factors for obtaining the least error and the most signal in high-throughput screening experiments.

These factors contribute to better morphological, spectral, and temporal resolution, allowing your experiments to show even small changes with less statistical error. In this article, we explain the influences of each factor and present specific considerations to make when selecting microtiter plates for imaging and high-content screening.

Read the Technical Note from ZEISS & Greiner Bio-One now!

How imaging requirements dictate the qualities of your microtiter plate

Let’s look at some critical factors for obtaining the most signal in high-content screening (HCS) experiments. Different materials for microtiter plates have an impact on imaging, e.g., in terms of transparency, homogeneity of surfaces or difficulty of surface modifications. Cyclic olefin materials such as Greiner Bio-One SCREENSTAR microtiter plates [1-3] have been developed to offer the overall best price-performance for a variety of applications.

Important factors for selecting microtiter plates for high-content screening

The flatness between and within wells and the design of the well bottom play a role, and the effect of bottom thickness on resolution and image quality can be considerable. The optimal bottom thickness is typically close to that of a cover glass: 0.17 mm. Short working distances for oil or water immersion lenses objectives lead to a higher resolution and image quality.

Dimensions and tolerances are crucial for adaptation to automated systems. All important dimensions of the microtiter plate should therefore comply with ANSI recommendations to facilitate adaptation and use in fully automated systems.

Well bottom elevation

A larger distance between the plate bottom and the outer rim, as often seen for classical screening microplates, can be a limiting factor for the choice of the objective. For highest image quality only microtiter plates with a recessed well bottom enable a complete periphery access for objectives with a high NA (Numerical Aperture) or immersion applications which typically have a short working distance.

Bottom thickness

Microscopic objectives are typically calibrated to a 170 µm bottom thickness, the standard thickness of coverslip glass. The typical bottom thickness of microtiter plates for high-content screening is in the range of 170 to 190 µm. This enables the use of high NA objectives with short working distances for the best imaging results.

Planarity of the microplate

The planarity of the microtiter plate is a decisive criterion and strongly depends on the bottom material. Glass bottom microtiter plates feature a maximum level of planarity due to its rigidity, but also cyclic olefin plates show good planarity at various plate densities. Those microtiter plates can significantly reduce the autofocus times and enhance the overall screening throughput.

Bottom material

To ensure best imaging results, only materials with a high optical quality should be used for the well bottom material. As discussed, glass followed by cyclic olefin foils achieve the best imaging results.

Surface chemistry

Finally, surface chemistry is an all-important factor of microtiter plates. Hydrophilic surfaces treated with cell cultures are suitable for cell based assays, untreated ones with a hydrophobic surface for biochemical assays.

Do you want to learn more about plastic labware for optimal results in modern life science microscopy for high-content screening? Download our corresponding application note, where experts from Greiner Bio-One and ZEISS share their knowledge.

Read the Technical Note from ZEISS & Greiner Bio-One now!

References

[1] Plastic Labware for Optimal Results in Modern Life Science Microscopy Using ZEISS Axio Observer and ZEISS Celldiscoverer 7. Technology Note. Philipp Wachter (Greiner Bio-One GmbH, Frickenhausen, Germany), Martin Gleisner, Volker Doering (Carl Zeiss Microscopy GmbH, Jena, Germany). February 2022 https://www.gbo.com/fileadmin/media/GBO-International/01_Downloads_BioScience/SALES_Application_Notes/Application_Note_GBO_labware_on_ZEISS_microscopes_EN.pdf

[2] SCREENSTAR: A 1536 Well Microplate for High Content and High Throughput Screening. Greiner Bio-One forum – Technical Notes and Applications for Laboratory Work No. 15 https://www.gbo.com/fileadmin/media/GBO-International/01_Downloads_BioScience/SALES_Scientific_Publications/F073120_Forum_No._15_SCREENSTAR.pdf

[3] SCREENSTAR and CELLview: Microplates for Advanced Microscopy. Greiner Bio-One forum – Technical Notes and Applications for Laboratory Work No. 18 https://www.gbo.com/fileadmin/media/GBO-International/01_Downloads_BioScience/SALES_Scientific_Publications/F073787_Forum_No._18_SCREENSTAR_CELLview.pdf