Magnetic 3D Bioprinting and the Applications of 3D Cell Culture

Magnetic three-dimensional (M3D) bioprinting shows great promise for the consistent production of three-dimensional (3D) cell cultures. In this article, we explore the different options for creating organoids, modeling in vitro lacrimal gland (LG) systems, and look at 3D bioprinting of human dental stem cells compared to mouse and porcine models.

Organoids do not need to be produced using animal-based extracellular matrix components!

Cell cultures are commonly prepared using matrix components. Popular commercially available products for this purpose produce a biologically active material that resembles the basic mammalian cellular matrix and provides a physiologically relevant environment.

Such products are derived, for example, from a mouse tumor rich in laminin, collagen, and other extracellular matrix (ECM) proteins, which carries an ethical downside, as the production process costs the lives of many animals. While researchers are often under the impression that organoids can be produced in only one way – using animal-based ECM components – this is not true! Organoids can also be produced without the use of an animal-based matrix, as we will see with 3D bioprinting [1].

Current biotechnologies for LG regeneration and improvement of DED

New in vitro and in vivo cell-based technologies are emerging that can enable drug discovery in dry eye disease and potential human transplantation techniques to regenerate LG tissues. Cell culture systems in 3D can fabricate cellularized matrices that retain morphology and a phenotype similar to in vivo tissues.

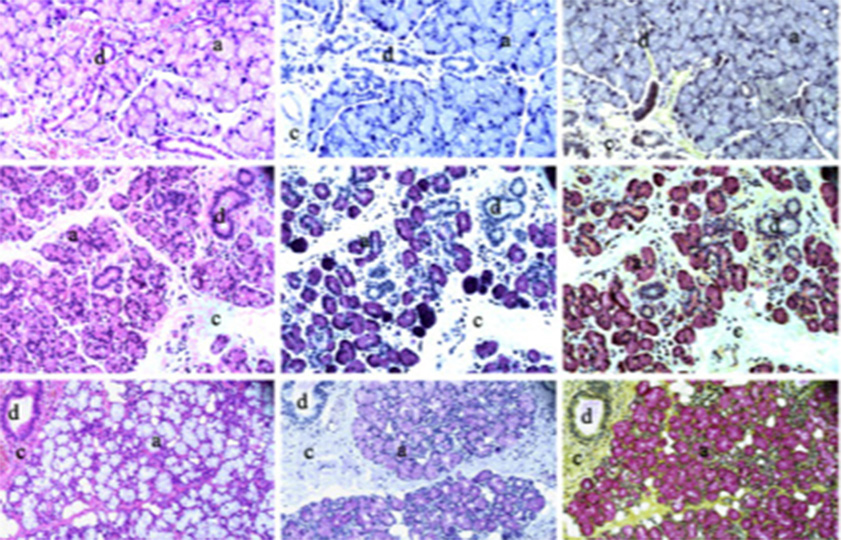

Cells in 3D co-cultures of rabbit conjunctival epithelium and LG, for example, can retain their functional and secretory markers mimicking in vivo conditions, making them suitable as a model for studying LG biology. The 3D culture systems used to generate organoids for LG transplantation can be produced in different ways: such as scaffold-free, scaffold-based, or via bioprinting [1].

Bioprinting 3D culture systems for LG biofabrication

Magnetic 3D Bioprinting enables uniform biofabrication and handling of spheroids/organoids for high-throughput analysis. With 3D Bioprinting, labeled cells can freely assemble in a controllable size within a shorter culture time.

Cells in suspension or adhered can be magnetized with the biocompatible NanoShuttle-PL commercialized by Greiner Bio-One, which bind electrostatically to the cell membrane during a short incubation period. The magnetized cells can then be 3D printed into vascular spheroidal or other structures by placing the culture plate on a ring- or point-shaped magnet. Thus, this technology surpasses the limitations of other high-throughput platforms [1].

NanoShuttle-PL for 3D Bioprinting has shown no deleterious effect on cells. Rodboon et al. demonstrated the first successful step toward the use of magnetic 3D (M3D) culture system for a consistent lacrisphere formation and expansion, leading to LG organoid biofabrication. Further studies are ongoing to determine whether the M3D culture system can recapitulate the LG native function for high-throughput analysis and validate the LG organoid M3D platform towards drug screening.

The applications of 3D cell culture are more diverse than you can imagine!

High-throughput strategies related to stem cells for drug discovery are a hot topic currently being discussed in the scientific community. High throughput is also of interest in stem cells for organoid generation [2]. A combinatorial approach is used to determine which factors, cofactors, and media produce a particular phenotype. Enabling this combinatorial approach is very important.

Scientists are often unaware of how useful M3D cell culture is for achieving these goals faster and cleaner. The diversity of cells is high and different conditions need to be tested to find out which ones produce the desired phenotype. 3D cell culture is ideal for this research purpose because it allows for high-throughput and miniaturization of the culture.

How does bioprinting and levitation with M3D work

A quick overview of how to use magnetic 3D cell culture (M3D) to produce 3D cell aggregates by bioprinting or by using levitation - gently, simply and easily.

Ready to enter the next level?

Please fill out this form and contact our experts today to find the perfect solution for you!

Don't miss our regular updates on scientific topics around 3D Cell Culture

References

[1] Rodboon T, Yodmuang S, Chaisuparat R, Ferreira JN. Development of high-throughput lacrimal gland organoid platforms for drug discovery in dry eye disease. SLAS Discov. 2022 Apr;27(3):151-158. doi: 10.1016/j.slasd.2021.11.002. Epub 2021 Dec 4. PMID: 35058190.

[2] Fang Y, Eglen RM. Three-Dimensional Cell Cultures in Drug Discovery and Development. SLAS Discov. 2017 Jun;22(5):456-472. doi: 10.1177/1087057117696795. Erratum in: SLAS Discov. 2021 Oct;26(9):NP1. PMID: 28520521; PMCID: PMC5448717.